Author: Le Quang Huy - Nguyen Huu Quyen

Vehicle air conditioning system

Introduction

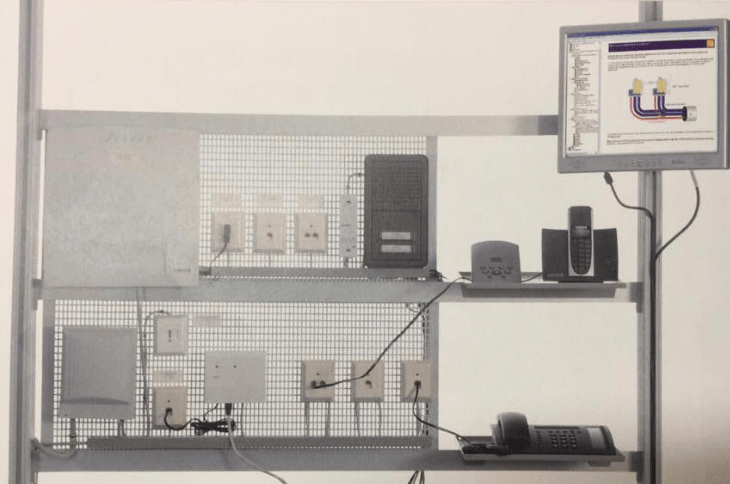

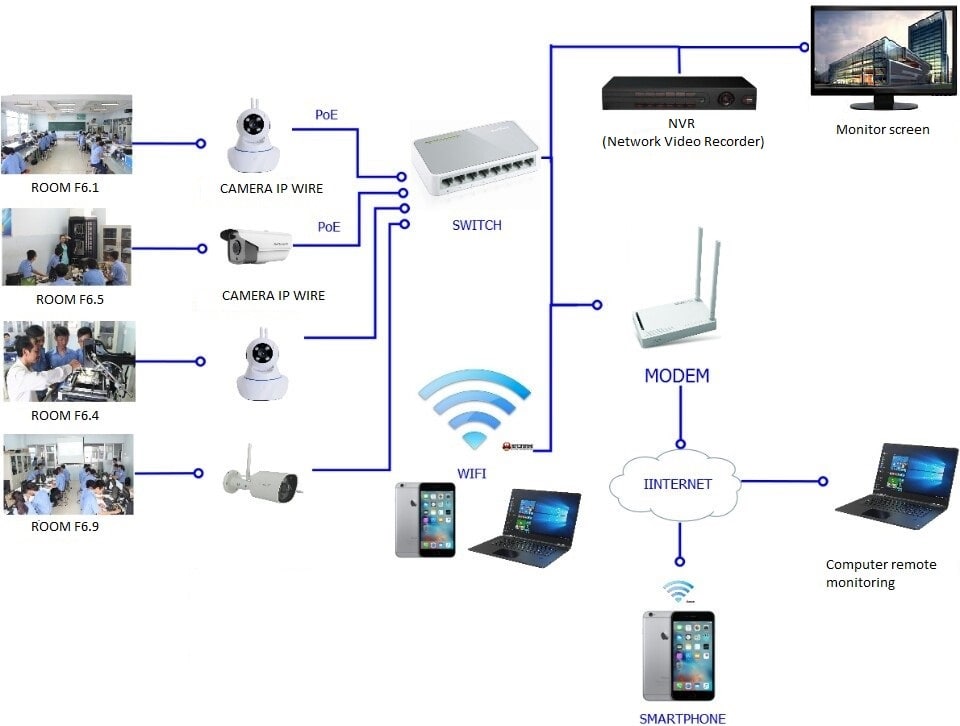

Vehicle air conditioning systems are used to cool down the vehicle interior. The cold air generated in the air conditioning system is transported by a fan into the vehicle interior.

Vehicle air conditioning systems include a compressor, a condenser with fan, an evaporator as air cooler with three stage fan and expansion valve.

The trainer operates with the 12VDC supply common in vehicles. An electric motor drives the compressor via a V-belt and a magnetic coupling. Thus, the compressor is controlled freely in speed by frequency converter to simulate the drive via the vehicle engine.

Learning Objectives / Experiments

- Principle of operation, design and handling of a vehicle air conditioning system.

- Typical components of a refrigeration system.

- Refrigeration circuit as thermodynamic cycle.

- Detection of typical faults and repair of a faulty air conditioning system.

- The utilization of teaching the subject: Practice vehicle air conditioning system.

Specifications

Electric motor

- Rotary current motor

- Speed adjustment via frequency converter: 500÷3000 rpm.

- Power: 4kW

Axial piston compressor

- Refrigeration capacity: approx. 3kW

- Condenser capacity: 6.6kW

- Evaporator capacity: 5.3kW

References

1. Ross Montgomery and Robert McDowall, Fundamentals of HVAC control systems.

2. American Society of Heating, Refrigerating and Air-Conditioning Engineers Inc, 2010 ASHRAE HANDBOOK REFRIGERATION, SI edition.

3. Yunus A. Cengel, Thermodynamics An Engineering Approach, Fifth edition.

4. Dr. William and S.Janna, Engineering Heat Transfer, Second edition.

5. Gunt, Metal work: Assembly and Production Technology Handbook.

Vietnamese

Vietnamese English

English