MOTIVATION

Computer numerical control (CNC) is the automation of machine tools by means of computers executing pre-programmed sequences of machine control commands [1]. The CNC machine have been applied in industrial at Vietnam since last decade of 20th century. At present time, there are a lot of factories use CNC machine in their manufacture process. However, the control techniques (software) and equipments must be imported. Only a few groups of Vietnamese scientist hold the control technologies and implement their knowledge into real CNC machine. This is a big gap of Vietnam’s industy. Furthermore, to understand about Central Control Unit in CNC machine is very useful for faculties in their lectures.

This project includes two targets: first, understanding and holding the control technologies in CNC lathe machine base on design and construction a real one; second, to build a system of lessons which is used for reseaching and teaching at Cao Thang Technical College.

METHODOLOGIES

Main task 1: To construct the CNC lathe machine

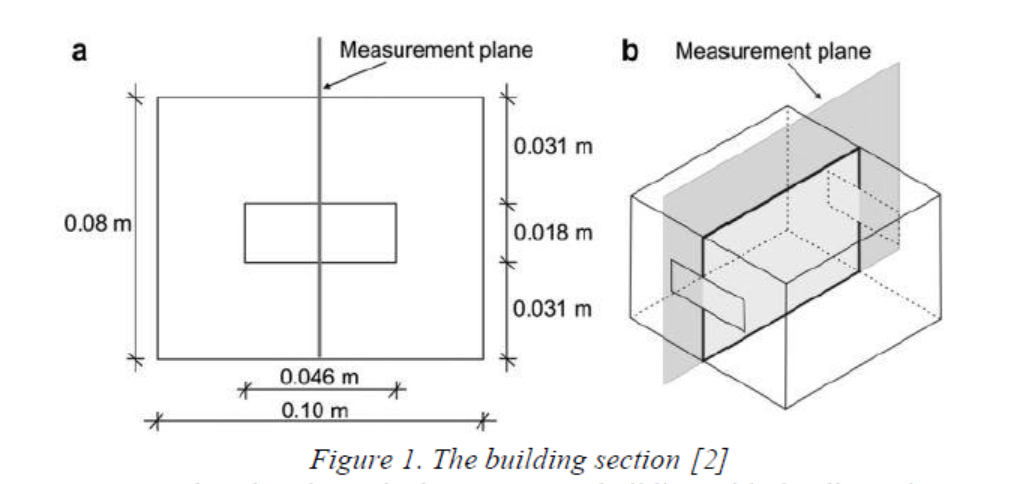

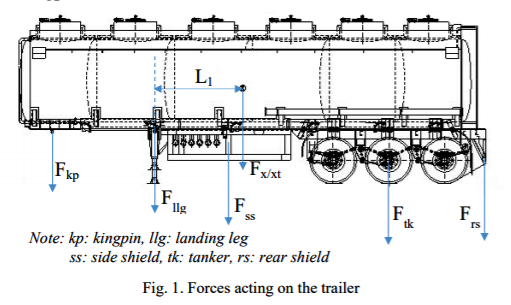

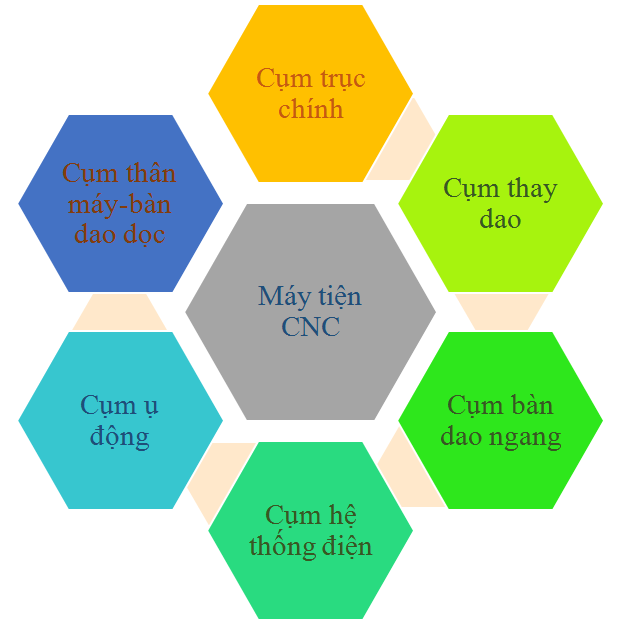

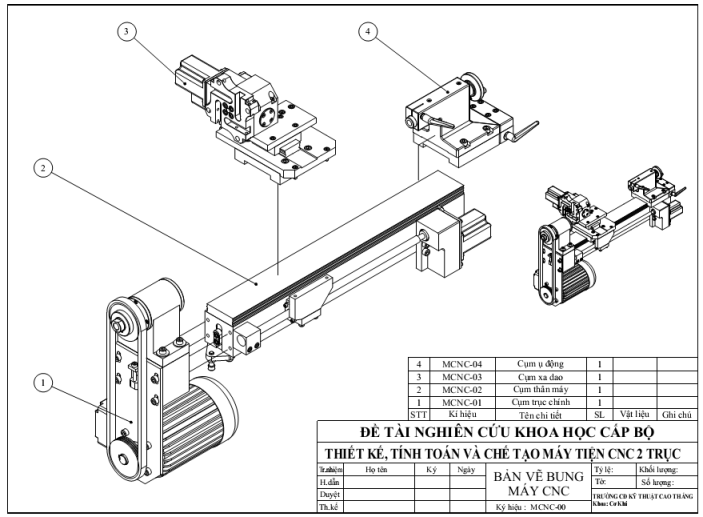

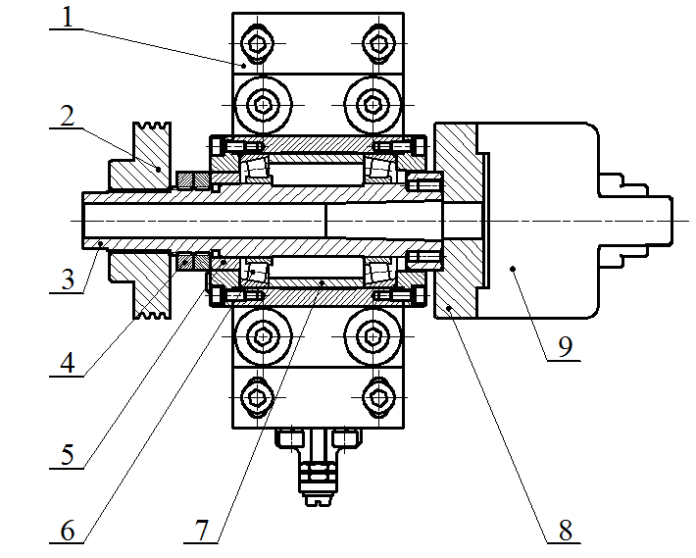

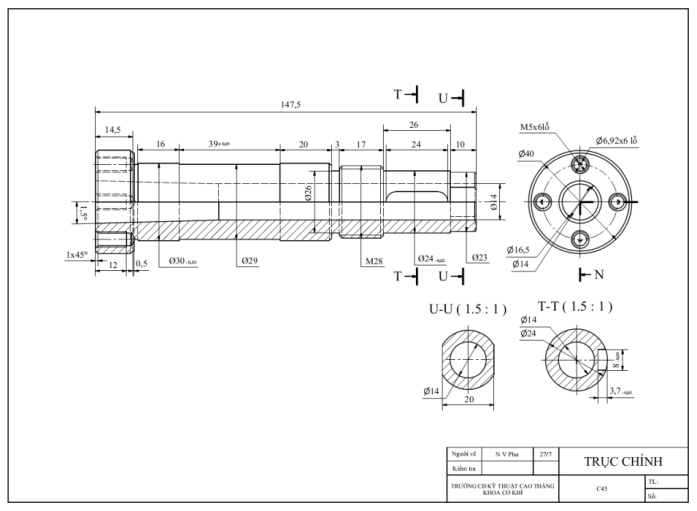

The lathe machine is designed and presented in Fig. 1 to Fig 4.

Figure 1. Main block functions in a CNC lathe machine.

Figure 2. The distribution of block functions in CNC lathe machine.

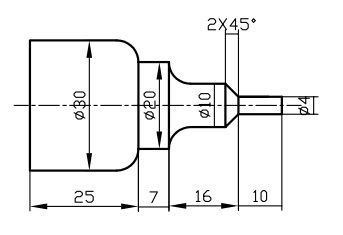

Figure 3. The struction of main axis block.

Figure 4 The detail drawing of main axis block function.

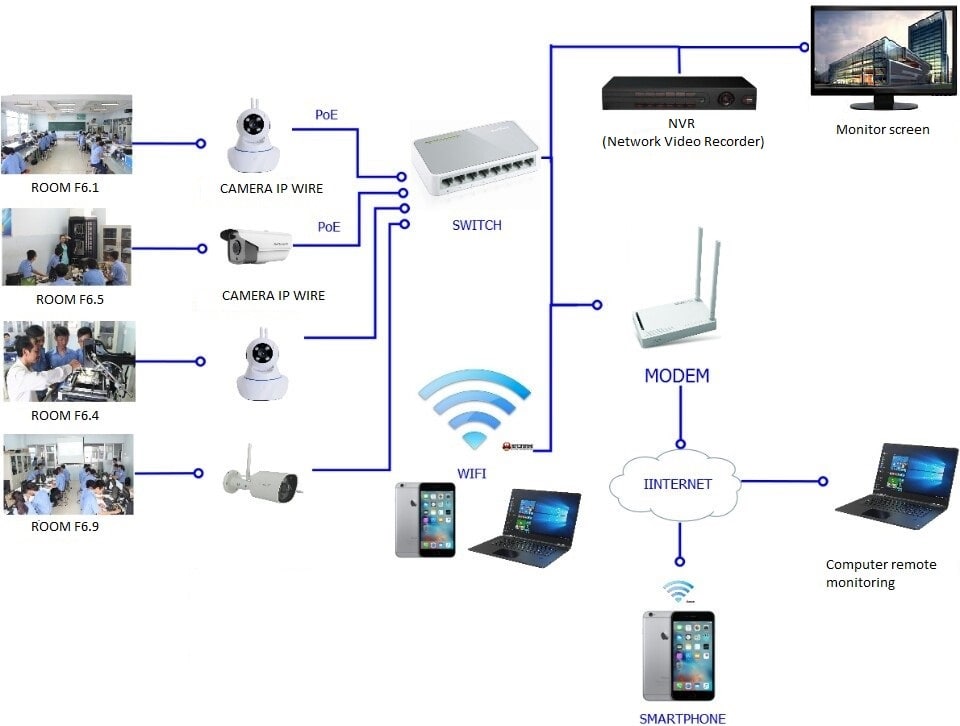

Main task 2: To build the Central Control Unit and programming.

Three solution are proposed for Central Control Unit as followings.

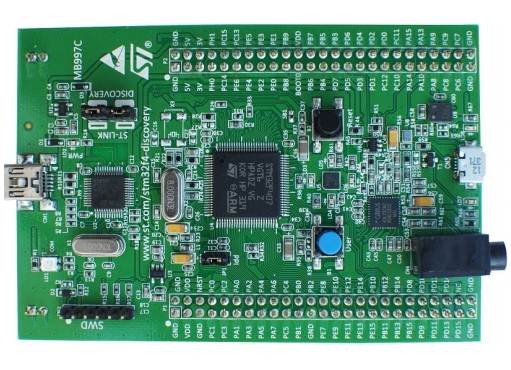

Solution1. Using the Arm Cortext Board and labtop

Figure 5 Discovery STM32F407 board.

Figure 6. Block function of Central Control Unit uses STM32F407 discovery board and personal computer.

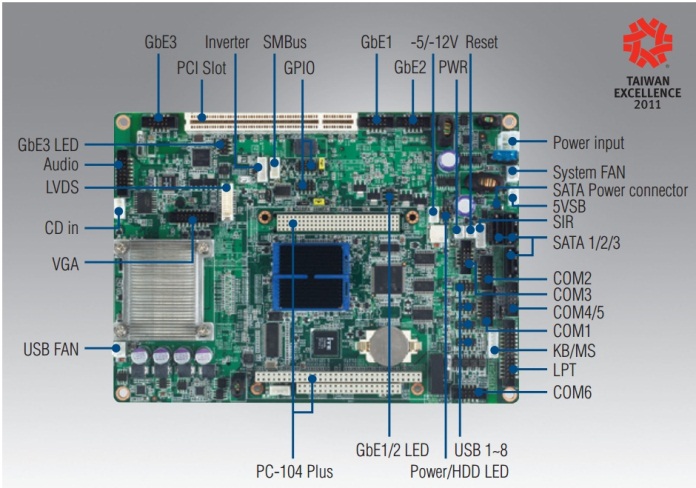

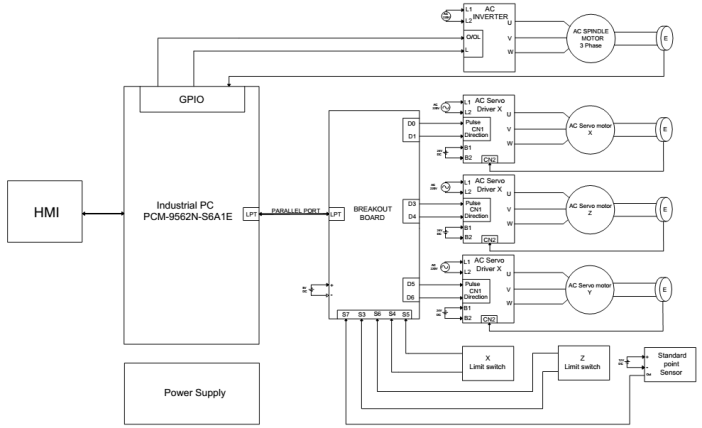

Solution 2. Using the Industrial Computer

Figure 7. Industrial computer PCM 9562 main board.

Figure 8. The wiring in second solution with PCM 9562.

Solution 3. Using the control board of NI

Figure 9. Card PCI 7354 with four axes control ports.

RESULTS

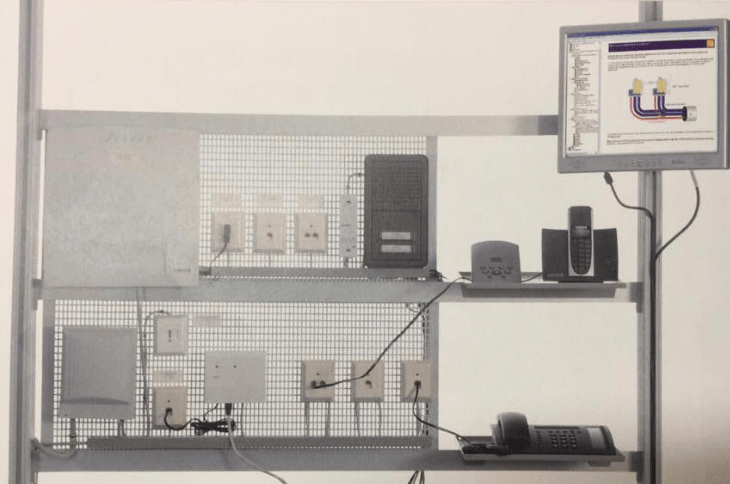

Three proposed solutions show the good results. The products are operated with high accurate. (Fig. 10 to Fig. 12)

Figure 10 The lathe CNC machine

Figure 11 The product without niple.

Figure 12 The product with niple

FUTURE WORKS

The Control Unit for three, four axes is interesting. The group of researchers in Cao Thang Technical College focus on this topic in next years continuously. The system of lessions is in the completing step. Implementing the Cetral Control Unit in arm robot is also employed by the other group at CTTC.

References

[1]. Brittain, James (1992), Alexanderson: Pioneer in American Electrical Engineering, Johns Hopkins University Press, ISBN 0-8018-4228-X.

[2] Zhou Kai. PC numerical control principle, system and application [M]. Beijing: Mechanical Industry Press, 2006

[3] Chen Zhexian, Wang Qingyang, Pei Hailong. Research and Design for Open-CNC System Task Management . Modular Machine Tool & Automatic Manufacturing Technique, 2010 (01): 98-101

[4] Wu Kangli, Li Bin, Chen Jihong. Implementation of NC Code Interpreter of Open Architecture NC System Platform . China Mechanical Engineering, 2006 ( 02 ): 61-64

[5] Xu Xiaoming, Wang Shuogui. Development of Code Compiler for PC-based Open CNC System . Machine Tool & Hydraulics, 2009 (11): 48-51

[6] Martinov GM., Kozak NV. Numerical control of large precision machining centers by the AxiOMA contol system. Russian Engineering Research 2015;35(7):534-538.

[7] Geetha A. Modelling a Computer Numerical Control Machine-2 Axis. Middle-East Journal of Scientific Research 2014;20(1):62-64.

Vietnamese

Vietnamese English

English